"It is important for us to have the direct contact to you to answer your product requests individual so that we are able to offer the best product solution"

"It is important for us to have the direct contact to you to answer your product requests individual so that we are able to offer the best product solution"

Anthony Dowell

Head of Sales

IBG Hydrotech GmbH

Anthony Dowell

Head of Sales

IBG Hydrotech GmbH

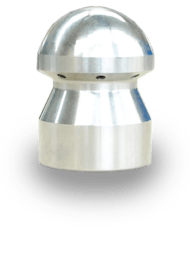

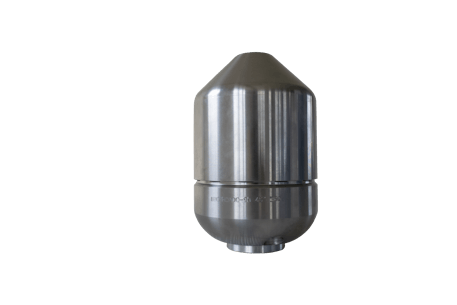

The Dracula is a universal cleaning nozzle with a large jet angle that allows easy cleaning through tight bends. In combination with the High Efficiency Nozzle-Series (designated ‘HW’), use of a mechanical cleaning tool can usually be avoided.

Applications: Cleaning of high polluted pipe networks because of high cleaning power; Pipes with tight bends; Tough debris

The Dracula is a universal cleaning nozzle with a large jet angle that allows easy cleaning through tight bends. In combination with the High Efficiency Nozzle-Series (designated ‘HW’), use of a mechanical cleaning tool can usually be avoided.

Applications: Cleaning of high polluted pipe networks because of high cleaning power; Pipes with tight bends; Tough debris

Water consumption:

> 350 ltr./min

Water consumption:

> 350 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

Yes

Front Spray:

Yes

Weight:

4,0 kg

Weight:

4,0 kg

Working Area:

150 - 600 mm

Working Area:

150 - 600 mm

SKU:

01 02 01 01 6 YY WW

SKU:

01 02 01 01 6 YY WW

Jet Angle:

Front: 0o Back: 25°

Jet Angle:

Front: 0o Back: 25°

Connection Thread:

1" | 1 1/4"

Connection Thread:

1" | 1 1/4"

Sand and sludge in the pipeline lead to reduced cross-section and increase friction losses. This reduces the total flow rate in the pipe. To prevent this, the pipe should be cleaned regularly to prevent full blockages.

Below you'll find effective nozzles to clean the sewer pipeline in no time.

Sand and sludge in the pipeline lead to reduced cross-section and increase friction losses. This reduces the total flow rate in the pipe. To prevent this, the pipe should be cleaned regularly to prevent full blockages.

Below you'll find effective nozzles to clean the sewer pipeline in no time.

Dracula Series

Working Area 150 - 600 mm

Dracula Series

Working Area 150 - 600 mm

RotorJiggler Series

Working Area 50 - 400 mm

RotorJiggler Series

Working Area 50 - 400 mm

HW Series

Working Area 50 - 800 mm

HW Series

Working Area 50 - 800 mm

Special requirements need specific tools. Therefore, special nozzle technology is also required for particularly tough soiling, special profiles or water-carrying lines.

Years of experience show who delivers what they promise. Therefore, our top 3 are listed below.

Special requirements need specific tools. Therefore, special nozzle technology is also required for particularly tough soiling, special profiles or water-carrying lines.

Years of experience show who delivers what they promise. Therefore, our top 3 are listed below.

Powerjet Series

Working Area 400 - 3.000 mm

Powerjet Series

Working Area 400 - 3.000 mm

GP Series

Working Area 50 - 400 mm

GP Series

Working Area 50 - 400 mm

Mega Series

Working Area 100 - 2.500 mm

Mega Series

Working Area 100 - 2.500 mm

The classic case. Root ingrowth in the sewer pipe.

We have selected the right nozzle for both the hard case and the early stage of root ingrowth.

The classic case. Root ingrowth in the sewer pipe.

We have selected the right nozzle for both the hard case and the early stage of root ingrowth.

Pilz Series

Working Area 10 - 150 mm

Pilz Series

Working Area 10 - 150 mm

Wiesel Series

Working Area 50 - 300 mm

Wiesel Series

Working Area 50 - 300 mm

Tristar Series

Working Area 20 - 600 mm

Tristar Series

Working Area 20 - 600 mm

Chain Rotor Series

Working Area 150 - 600 mm

Chain Rotor Series

Working Area 150 - 600 mm

Classic Chain Rotor Series

Working Area 100 - 300 mm

Classic Chain Rotor Series

Working Area 100 - 300 mm

Fat is not soluble in water and therefore floats on the surface. This law of nature is not suspended underground either. That is why municipalities and cities regularly have problems with lumps of grease clogging the sewage system.

The following nozzles help local users to cope with this problem as well. But should be said again at this point: Grease goes in the trash, not down the drain.

Fat is not soluble in water and therefore floats on the surface. This law of nature is not suspended underground either. That is why municipalities and cities regularly have problems with lumps of grease clogging the sewage system.

The following nozzles help local users to cope with this problem as well. But should be said again at this point: Grease goes in the trash, not down the drain.

Abano Series

Working Area 150 - 800 mm

Abano Series

Working Area 150 - 800 mm

Rondo Series

Working Area 50 - 300 mm

Rondo Series

Working Area 50 - 300 mm

Roto-Max Series

Working Area 80 - 600 mm

Roto-Max Series

Working Area 80 - 600 mm

Gutter cleaning is for professionals. Residues remain on the elevations and pile up. This must be prevented. Therefore, special nozzle technology is needed. These little wonders of technology help to free pipesockets and gutters from all kinds of dirt in no time. Without leftovers.

Gutter cleaning is for professionals. Residues remain on the elevations and pile up. This must be prevented. Therefore, special nozzle technology is needed. These little wonders of technology help to free pipesockets and gutters from all kinds of dirt in no time. Without leftovers.

WaMax with socket cutter

Working Area 100 - 1000 mm

WaMax with socket cutter

Working Area 100 - 1000 mm

Gutter nozzle Series

Working Area 80 - 300 mm

Gutter nozzle Series

Working Area 80 - 300 mm

The so called HW-Series raises standards in the cleaning of heavily polluted pipes (with debris and lose rubble). The efficient nozzle converts the water supply from the hose into jets of unrivalled cleaning and propulsion power.

Applications: Streakless cleaning; Removal of debris and rubble;

Strong pollution and debris

The so called HW-Series raises standards in the cleaning of heavily polluted pipes (with debris and lose rubble). The efficient nozzle converts the water supply from the hose into jets of unrivalled cleaning and propulsion power.

Applications: Streakless cleaning; Removal of debris and rubble;

Strong pollution and debris

Water consumption:

> 300 ltr./min

Water consumption:

> 300 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

No

Front Spray:

No

Weight:

0,24 - 7,9 kg

Weight:

0,24 - 7,9 kg

Working Area:

50 - 800 mm

Working Area:

50 - 800 mm

SKU:

06 03 01 01 3 YY 06

SKU:

06 03 01 01 3 YY 06

Jet Angle:

Back: 6°/ 10° / 12° / 18°

Jet Angle:

Back: 6°/ 10° / 12° / 18°

Connection Thread:

1/2" up to 1 1/4"

Connection Thread:

1/2" up to 1 1/4"

HW 70

50 - 300 mm

HW 70

50 - 300 mm

HW 75

100 - 400 mm

HW 75

100 - 400 mm

HW 100

200 - 600 mm

HW 100

200 - 600 mm

HW 110

300 - 800 mm

HW 110

300 - 800 mm

Available Options:

Available Options:

Front Spray:

No

Front Spray:

No

The Vibration Nozzle RotorJiggler is the first part of the foundation of a new concept for the easy removal of mineral deposits, concrete, building materials and slag and similar materials in pipe and sewer systems.

Using the special vibration frequency field, materials to be removed are fractured insitu and broken loose from the pipe or sewer wall. These nozzles make the cleaning of drainage pipes in tunnels, culverts and specialist areas such as beneath landfill sites possible.

The Vibration Nozzle RotorJiggler is the first part of the foundation of a new concept for the easy removal of mineral deposits, concrete, building materials and slag and similar materials in pipe and sewer systems.

Using the special vibration frequency field, materials to be removed are fractured insitu and broken loose from the pipe or sewer wall. These nozzles make the cleaning of drainage pipes in tunnels, culverts and specialist areas such as beneath landfill sites possible.

Water consumption:

25 - 250 ltr./min

Water consumption:

25 - 250 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Weight:

0,3 - 2,6 kg

Weight:

0,3 - 2,6 kg

Working Area:

50 - 400 mm

Working Area:

50 - 400 mm

SKU:

05 03 01 01 2 03 02

SKU:

05 03 01 01 2 03 02

Jet Angle:

Back: 15o

Jet Angle:

Back: 15o

Connection Thread:

1/4" - 1"

Connection Thread:

1/4" - 1"

RotorJiggler 1/4"

50 - 125 mm

RotorJiggler 1/4"

50 - 125 mm

RotorJiggler 1/2"

80 - 150 mm

RotorJiggler 1/2"

80 - 150 mm

RotorJiggler 3/4"

150 - 300 mm

RotorJiggler 3/4"

150 - 300 mm

RotorJiggler 1"

150 - 400 mm

RotorJiggler 1"

150 - 400 mm

Available Options:

Available Options:

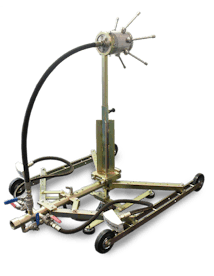

The PowerJet-Series is the latest generation of our ejector nozzles. These are especially suitable for the cleaning of large profiles water-bearing pipes and sewers pipes.

With optimal conversion of incoming water pressure and flow rate the performance is increased with less power input. With a flow of only 280 litres per minute and 130 bar pressure huge amounts of heavy materials (stones, mud and paper or cellulose) can be removed.

The PowerJet-Series is the latest generation of our ejector nozzles. These are especially suitable for the cleaning of large profiles water-bearing pipes and sewers pipes.

With optimal conversion of incoming water pressure and flow rate the performance is increased with less power input. With a flow of only 280 litres per minute and 130 bar pressure huge amounts of heavy materials (stones, mud and paper or cellulose) can be removed.

Water consumption:

> 400 ltr./min

Water consumption:

> 400 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

No

Front Spray:

No

Weight:

35 - 55 kg

Weight:

35 - 55 kg

Working Area:

400 - 3000 mm

Working Area:

400 - 3000 mm

SKU:

0106020150604

SKU:

0106020150604

Jet Angle:

Back: 0o

Jet Angle:

Back: 0o

Connection Thread:

1" | 1 1/2" |1 1/4"

Connection Thread:

1" | 1 1/2" |1 1/4"

PowerJet 100

400 - 1000 mm

PowerJet 100

400 - 1000 mm

PowerJet 500

800 - 2000 mm

PowerJet 500

800 - 2000 mm

PowerJet 600

1000 - 3000 mm

PowerJet 600

1000 - 3000 mm

Available Options:

Available Options:

The Mega nozzle is designed to operate economically with maximum penetrating power.

All water jets are concentrated on the bottom of the pipe to remove heavy solids, silt, sand and sludge.

The Mega nozzle is designed to operate economically with maximum penetrating power.

All water jets are concentrated on the bottom of the pipe to remove heavy solids, silt, sand and sludge.

Water consumption:

> 400 ltr./min

Water consumption:

> 400 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

No

Front Spray:

No

Weight:

1,4 - 22 kg

Weight:

1,4 - 22 kg

Working Area:

100 - 2500 mm

Working Area:

100 - 2500 mm

SKU:

0106020150604

SKU:

0106020150604

Jet Angle:

Back: 0o - 25o

Jet Angle:

Back: 0o - 25o

Connection Thread:

1/2" - 1 1/4"

Connection Thread:

1/2" - 1 1/4"

Mega 3

100 - 300 mm

Mega 3

100 - 300 mm

Mega 5

300 - 600 mm

Mega 5

300 - 600 mm

Mega 6

600 - 2500 mm

Mega 6

600 - 2500 mm

Available Options:

Available Options:

Mega 8

300 - 1000 mm

Mega 8

300 - 1000 mm

The Pilz is designed for general cleaning of house connections and small pipe diameters with low to medium debris accumulations of limescale, soap and grease.

Applications: House connections and small pipes; Standard cleaning

Degree of contamination: Easy to medium debris of limestone, soap and grease

Operating pressure: Max. 200 bar

The Pilz is designed for general cleaning of house connections and small pipe diameters with low to medium debris accumulations of limescale, soap and grease.

Applications: House connections and small pipes; Standard cleaning

Degree of contamination: Easy to medium debris of limestone, soap and grease

Operating pressure: Max. 200 bar

Water consumption:

25 - 100 ltr./min

Water consumption:

25 - 100 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

Yes

Front Spray:

Yes

Weight:

0,008 - 0,6 kg

Weight:

0,008 - 0,6 kg

Working Area:

10 - 150 mm

Working Area:

10 - 150 mm

SKU:

12 01 01 XX 1 YY ZZ

SKU:

12 01 01 XX 1 YY ZZ

Jet Angle:

Front: 0°-20° Back: 30°:

Jet Angle:

Front: 0°-20° Back: 30°:

Connection Thread:

1/8" | 1/4" | 3/8"| 1/2"

Connection Thread:

1/8" | 1/4" | 3/8"| 1/2"

Pilz 1/8"

10 - 30 mm

Pilz 1/8"

10 - 30 mm

Pilz 1/4"

50 - 100 mm

Pilz 1/4"

50 - 100 mm

Pilz 3/8"

50 - 150 mm

Pilz 3/8"

50 - 150 mm

Available Options:

Available Options:

Pilz 1/2"

50 - 150 mm

Pilz 1/2"

50 - 150 mm

The Chisel Point Nozzle TriStar was designed to remove blockages and full pipe obstructions like roots and other deposits. An economical application is guaranteed using the combination of the forward-facing jets with the pointed drill and sharp cutting edges.

Applications: General pipe cleaning; Removal of heavy blockages, roots

Degree of contamination: Normal to heavy polluted

The Chisel Point Nozzle TriStar was designed to remove blockages and full pipe obstructions like roots and other deposits. An economical application is guaranteed using the combination of the forward-facing jets with the pointed drill and sharp cutting edges.

Applications: General pipe cleaning; Removal of heavy blockages, roots

Degree of contamination: Normal to heavy polluted

Water consumption:

> 250 ltr./min

Water consumption:

> 250 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

Yes

Front Spray:

Yes

Weight:

0,02 - 2 kg

Weight:

0,02 - 2 kg

Working Area:

20 - 600 mm

Working Area:

20 - 600 mm

SKU:

12 04 01 01 1 YY 10

SKU:

12 04 01 01 1 YY 10

Jet Angle:

Front: 0° and 20°

Back: 20° and 30°

Jet Angle:

Front: 0° and 20°

Back: 20° and 30°

Connection Thread:

1/8" - 1 1/4"

Connection Thread:

1/8" - 1 1/4"

TriStar drilled 1/8"

20 - 50 mm

TriStar drilled 1/8"

20 - 50 mm

TriStar drilled 3/8"

80 - 150 mm

TriStar drilled 3/8"

80 - 150 mm

TriStar drilled 1/4"

50 - 80 mm

TriStar drilled 1/4"

50 - 80 mm

Available Options:

Available Options:

TriStar drilled 1/2"

80 - 150 mm

TriStar drilled 1/2"

80 - 150 mm

TriStar LAK 1/2"

80 - 150 mm

TriStar LAK 1/2"

80 - 150 mm

TriStar LAK 1"

150 - 300 mm

TriStar LAK 1"

150 - 300 mm

TriStar F 3/4"

100 - 200 mm

TriStar F 3/4"

100 - 200 mm

TriStar F 1"

200 - 500 mm

TriStar F 1"

200 - 500 mm

TriStar F 1 1/4"

250 - 600 mm

TriStar F 1 1/4"

250 - 600 mm

When using ABANO nozzle technology about 15% less drive power is needed. The energy saved can be used for suction work. Furthermore, the cross-sectional area of the nozzle inserts is reduced by about 15%. This means there is a huge increase of pressure at the nozzle inserts with minimum back pressure (approximately 1 bar).

This new technology differs in design as compared with common round spray technologies on the market with increased cleaning performance whilst offering less energy requirement and material input.

When using ABANO nozzle technology about 15% less drive power is needed. The energy saved can be used for suction work. Furthermore, the cross-sectional area of the nozzle inserts is reduced by about 15%. This means there is a huge increase of pressure at the nozzle inserts with minimum back pressure (approximately 1 bar).

This new technology differs in design as compared with common round spray technologies on the market with increased cleaning performance whilst offering less energy requirement and material input.

Water consumption:

> 400 ltr./min

Water consumption:

> 400 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

No

Front Spray:

No

Weight:

4,5 - 6,5 kg

Weight:

4,5 - 6,5 kg

Working Area:

150 - 800 mm

Working Area:

150 - 800 mm

SKU:

0106020150604

SKU:

0106020150604

Jet Angle:

Back: 25o x 25o

Jet Angle:

Back: 25o x 25o

Connection Thread:

1" | 1 1/4"

Connection Thread:

1" | 1 1/4"

Abano 12 1"

150 - 400 mm

Abano 12 1"

150 - 400 mm

Abano 16 1"

150 - 400 mm

Abano 16 1"

150 - 400 mm

Abano 12 1 1/4"

200 - 600 mm

Abano 12 1 1/4"

200 - 600 mm

Available Options:

Available Options:

Abano 16 1 1/4""

200 - 600 mm

Abano 16 1 1/4""

200 - 600 mm

Monte Abano 16 1"

250 - 800 mm

Monte Abano 16 1"

250 - 800 mm

Monte Abano 16 1 1/4""

250 - 800 mm

Monte Abano 16 1 1/4""

250 - 800 mm

The newly designed and engineered RotoMax is capable of successfully removing the toughest deposits and scale with its high cleaning efficiency and by using recycled water.

Applications: Intense and fast removal of grease and deposits; Networks up to ID 2.000 (79″) and egg-shaped pipe profiles

Degree of contamination: Heavy pollution

Operating pressure: Max. 200 bar

The newly designed and engineered RotoMax is capable of successfully removing the toughest deposits and scale with its high cleaning efficiency and by using recycled water.

Applications: Intense and fast removal of grease and deposits; Networks up to ID 2.000 (79″) and egg-shaped pipe profiles

Degree of contamination: Heavy pollution

Operating pressure: Max. 200 bar

Water consumption:

> 350 ltr./min

Water consumption:

> 350 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

No

Front Spray:

No

Weight:

0,97 - 7,3 kg

Weight:

0,97 - 7,3 kg

Working Area:

80 - 600 mm

Working Area:

80 - 600 mm

SKU:

0106020150604

SKU:

0106020150604

Jet Angle:

Back: 15o

Jet Angle:

Back: 15o

Connection Thread:

1/2" | 3/4"| 1"| 1 1/4"

Connection Thread:

1/2" | 3/4"| 1"| 1 1/4"

RotoMax 50 1/2"

80 - 250 mm

RotoMax 50 1/2"

80 - 250 mm

RotoMax 80 1"

200 - 600 mm

RotoMax 80 1"

200 - 600 mm

RotoMax 50 3/4"

80 - 300 mm

RotoMax 50 3/4"

80 - 300 mm

Available Options:

Available Options:

RotoMax 110 1 1/4"

250 - 600 mm

RotoMax 110 1 1/4"

250 - 600 mm

The Rondo offers excellent performance in the cleaning process due to increased efficiency as well as low maintenance. It offers a powerful, all around pipe coverage that removes soap, grease and bitumen.

Applications: Networks polluted with soap, grease, bitumen Preparation before video inspection

Degree of contamination: Normal pollution

Operating pressure: Max. 300 bar

The Rondo offers excellent performance in the cleaning process due to increased efficiency as well as low maintenance. It offers a powerful, all around pipe coverage that removes soap, grease and bitumen.

Applications: Networks polluted with soap, grease, bitumen Preparation before video inspection

Degree of contamination: Normal pollution

Operating pressure: Max. 300 bar

Water consumption:

> 200 ltr./min

Water consumption:

> 200 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

No

Front Spray:

No

Weight:

0,22 - 1,32 kg

Weight:

0,22 - 1,32 kg

Working Area:

50 - 300 mm

Working Area:

50 - 300 mm

SKU:

03 00 05 01 2 06 45

SKU:

03 00 05 01 2 06 45

Jet Angle:

Back: 15o

Jet Angle:

Back: 15o

Connection Thread:

1/4" - 1 1/4"

Connection Thread:

1/4" - 1 1/4"

Rondo 35 1/2"

50 - 125 mm

Rondo 35 1/2"

50 - 125 mm

Rondo 50 3/4"

100 - 200 mm

Rondo 50 3/4"

100 - 200 mm

Rondo 40 1/2"

80 - 150 mm

Rondo 40 1/2"

80 - 150 mm

Available Options:

Available Options:

Rondo 60 1"

150 - 300 mm

Rondo 60 1"

150 - 300 mm

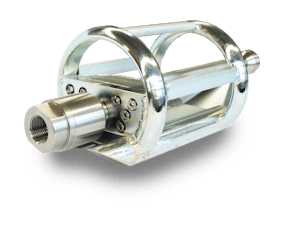

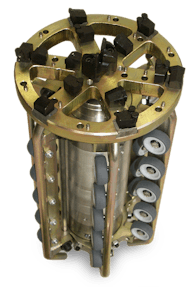

For the toughest applications: The WaMax is a world-leading milling system used for the removal of roots, mineral deposits, concrete and protruding sockets as well as for pipe preparation ahead of rehabilitation work.

These different applications are made possible by the use of various guide cages and milling heads. There are many different applications and location opportunities offered when using this system.

For the toughest applications: The WaMax is a world-leading milling system used for the removal of roots, mineral deposits, concrete and protruding sockets as well as for pipe preparation ahead of rehabilitation work.

These different applications are made possible by the use of various guide cages and milling heads. There are many different applications and location opportunities offered when using this system.

Water consumption:

> 400 ltr./min

Water consumption:

> 400 ltr./min

Radial Spray:

//

Radial Spray:

//

Back Spray:

No

Back Spray:

No

Front Spray:

No

Front Spray:

No

Weight:

7,5 - 37,4 kg

Weight:

7,5 - 37,4 kg

Working Area:

100 - 1.000 mm

Working Area:

100 - 1.000 mm

SKU:

05 01 01 01 6 04 00

SKU:

05 01 01 01 6 04 00

Jet Angle:

//

Jet Angle:

//

Connection Thread:

3/4" - 1 1/4"

Connection Thread:

3/4" - 1 1/4"

WaMax 100

100 - 200 mm

WaMax 100

100 - 200 mm

WaMax 300

300 - 1.000 mm

WaMax 300

300 - 1.000 mm

WaMax 200

150 - 600 mm

WaMax 200

150 - 600 mm

Available Options:

Available Options:

News | Trenchless Technology

News | Trenchless Technology

The First 2 in 1 Cutting and Inspection Robot

The First 2 in 1 Cutting and Inspection Robot

Digitalisation has also arrived in trenchless sewer rehabilitation.

The new HC² from IBG HydroTech GmbH impresses with the latest camera technology in 4K quality and 10x optical and 16x digital zoom. Thanks to advanced sensor technology and thermal imaging camera, t-sections in the sewer can be precisely identified, making incorrect milling almost impossible.

Specially developed, intelligent „self-tests“ prevent failures on the construction site and drastically reduce the error rate.

All eyes on the 2-in-1 add-on. IBG is presenting the first ever milling and inspection robot. Within just one flick the milling head is swapped for the HQ-CCTV-Camera.

Digitalisation has also arrived in trenchless sewer rehabilitation.

The new HC² from IBG HydroTech GmbH impresses with the latest camera technology in 4K quality and 10x optical and 16x digital zoom. Thanks to advanced sensor technology and thermal imaging camera, t-sections in the sewer can be precisely identified, making incorrect milling almost impossible.

Specially developed, intelligent „self-tests“ prevent failures on the construction site and drastically reduce the error rate.

All eyes on the 2-in-1 add-on. IBG is presenting the first ever milling and inspection robot. Within just one flick the milling head is swapped for the HQ-CCTV-Camera.

Don't waste time.

Take the right nozzle!

Don't waste time.

Take the right nozzle!

The GP 150 consists of a cage system with variable width and height for use in large profile sewer pipes including round-, egg- and square profiles, as well as profiles with a dry weather gutter.

The modular-design system is constructed in such a way that the user can operate in a specific profile size with a minimum of components and assembly requirements.

The GP 150 consists of a cage system with variable width and height for use in large profile sewer pipes including round-, egg- and square profiles, as well as profiles with a dry weather gutter.

The modular-design system is constructed in such a way that the user can operate in a specific profile size with a minimum of components and assembly requirements.

Water consumption:

25 - 250 ltr./min

Water consumption:

25 - 250 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

Yes

Front Spray:

Yes

Weight:

0,3 - 2,6 kg

Weight:

0,3 - 2,6 kg

Working Area:

500 - 2000 mm

Working Area:

500 - 2000 mm

SKU:

0106020150604

SKU:

0106020150604

Jet Angle:

Front: 0o Back: 25o

Jet Angle:

Front: 0o Back: 25o

Connection Thread:

1 1/4"

Connection Thread:

1 1/4"

GP 150

500 - 2000 mm

GP 150

500 - 2000 mm

Available Options:

Available Options:

Dracula 1"

100 - 400 mm

Dracula 1"

100 - 400 mm

Available Options:

Available Options:

Watch the making of the HC² here:

Watch the making of the HC² here:

Dracula 1 1/4"

150 - 600 mm

Dracula 1 1/4"

150 - 600 mm

Wiesel Series

Wiesel Series

The standard nozzles made of partially hardened VA steel, are ideally suited for standard cleaning of smaller pipes and house connections.

Application: House connections and smaller pipes with light to medium lime and grease deposits, standard cleaning

The standard nozzles made of partially hardened VA steel, are ideally suited for standard cleaning of smaller pipes and house connections.

Application: House connections and smaller pipes with light to medium lime and grease deposits, standard cleaning

Water consumption:

25 - 250 ltr./min

Water consumption:

25 - 250 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

Yes

Front Spray:

Yes

Weight:

0,3 - 2,6 kg

Weight:

0,3 - 2,6 kg

Working Area:

50 - 300 mm

Working Area:

50 - 300 mm

SKU:

0106020150604

SKU:

0106020150604

Jet Angle:

Front: 0o Back: 25o

Jet Angle:

Front: 0o Back: 25o

Connection Thread:

1/2" | 1 1/4"

Connection Thread:

1/2" | 1 1/4"

Wiesel 3/4"

80 - 250 mm

Wiesel 3/4"

80 - 250 mm

Wiesel 1"

100 - 300 mm

Wiesel 1"

100 - 300 mm

Available Options:

Available Options:

Combi Chain Rotor Series

Combi Chain Rotor Series

This innovative and highly reliable system can be used with different chain sets and is most effective when used in combination with our various cage designs and offers superior drive and thrust. The Recycling version that can be used with recycled water is also suitable for under water applications.

Applications: Removal of various deposits and roots; High milling performance

Operating pressure: Max. 200 bar

This innovative and highly reliable system can be used with different chain sets and is most effective when used in combination with our various cage designs and offers superior drive and thrust. The Recycling version that can be used with recycled water is also suitable for under water applications.

Applications: Removal of various deposits and roots; High milling performance

Operating pressure: Max. 200 bar

Water consumption:

> 350 ltr./min

Water consumption:

> 350 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Front Spray:

No

Front Spray:

No

Weight:

2,3 - 8,5 kg

Weight:

2,3 - 8,5 kg

Working Area:

150 - 600 mm

Working Area:

150 - 600 mm

SKU:

04 03 02 01 4 03 03

SKU:

04 03 02 01 4 03 03

Jet Angle:

Back: 15o

Jet Angle:

Back: 15o

Connection Thread:

1/2" | 3/4"| 1"| 1 1/4"

Connection Thread:

1/2" | 3/4"| 1"| 1 1/4"

Combi Chain Rotor 1/2"

100 - 200 mm

Combi Chain Rotor 1/2"

100 - 200 mm

Combi Chain Rotor 3/4"

150 - 400 mm

Combi Chain Rotor 3/4"

150 - 400 mm

Combi Chain Rotor 1"

150 - 400 mm

Combi Chain Rotor 1"

150 - 400 mm

Available Options:

Available Options:

Combi Chain Rotor 1 1/4"

200 - 600 mm

Combi Chain Rotor 1 1/4"

200 - 600 mm

News | Trenchless Technology

News | Trenchless Technology

Pressure pipe lining made easy

IBB16 - Rehabilitation system for pressure water pipes and drinking water pipes

Pressure pipe lining made easy

IBB16 - Rehabilitation system for pressure water pipes and drinking water pipes

The IBB16® system is a hybrid pipe relining (without connection to the old pipe) that can be used for the rehabilitation of pressure pipes.

The system combines two pipe liners with different properties to meet the necessary criteria for the rehabilitation of a pressurized water pipe. The system combines the IBG UV + steam systems to form the IBB16® system.

The system can be used in pressure lines up to an operating pressure of 16 bar (232 psi).

The IBB16® system is a hybrid pipe relining (without connection to the old pipe) that can be used for the rehabilitation of pressure pipes.

The system combines two pipe liners with different properties to meet the necessary criteria for the rehabilitation of a pressurized water pipe. The system combines the IBG UV + steam systems to form the IBB16® system.

The system can be used in pressure lines up to an operating pressure of 16 bar (232 psi).

Back Spray:

Yes

Back Spray:

Yes

Working Area:

50 - 300 mm

Working Area:

50 - 300 mm

Jet Angle:

Front: 0o Back: 25o

Jet Angle:

Front: 0o Back: 25o

Combi Chain Rotor Series

Combi Chain Rotor Series

This innovative and highly reliable system can be used with different chain sets and is most effective when used in combination with our various cage designs and offers superior drive and thrust. The Recycling version that can be used with recycled water is also suitable for under water applications.

Applications: Removal of various deposits and roots; High milling performance

Operating pressure: Max. 200 bar

This innovative and highly reliable system can be used with different chain sets and is most effective when used in combination with our various cage designs and offers superior drive and thrust. The Recycling version that can be used with recycled water is also suitable for under water applications.

Applications: Removal of various deposits and roots; High milling performance

Operating pressure: Max. 200 bar

Water consumption:

60 - 600 ltr./min

Water consumption:

60 - 600 ltr./min

Radial Spray:

No

Radial Spray:

No

Back Spray:

Yes

Back Spray:

Yes

Weight:

1,7 - 3,3 kg

Weight:

1,7 - 3,3 kg

Advantages:

Worldwide drinking water certification | High static load capacity | Independence from old pipe | Small excavation pits | Low transport costs and little space required on the construction site | Lengths up to 300m are possible without problems | Drinking water law

Advantages:

Worldwide drinking water certification | High static load capacity | Independence from old pipe | Small excavation pits | Low transport costs and little space required on the construction site | Lengths up to 300m are possible without problems | Drinking water law